DTF transfer by size is a foundational concept for anyone printing designs on apparel, guiding how artwork sits on garments and ensuring professional, readable results. Using a DTF transfer sizing chart and a dedicated DTF transfer size guide helps you standardize designs across runs, from event T-shirts to branded hoodies. When you follow a DTF printing size guide and consider how to choose transfer size for T-shirts, you safeguard proportions, legibility, and visual impact. Portability across garment types matters, so you’ll want to account for differences between T-shirts and DTF transfer for hoodies to maintain consistency. This introductory overview shows practical tips, charts, and examples to help you make informed decisions.

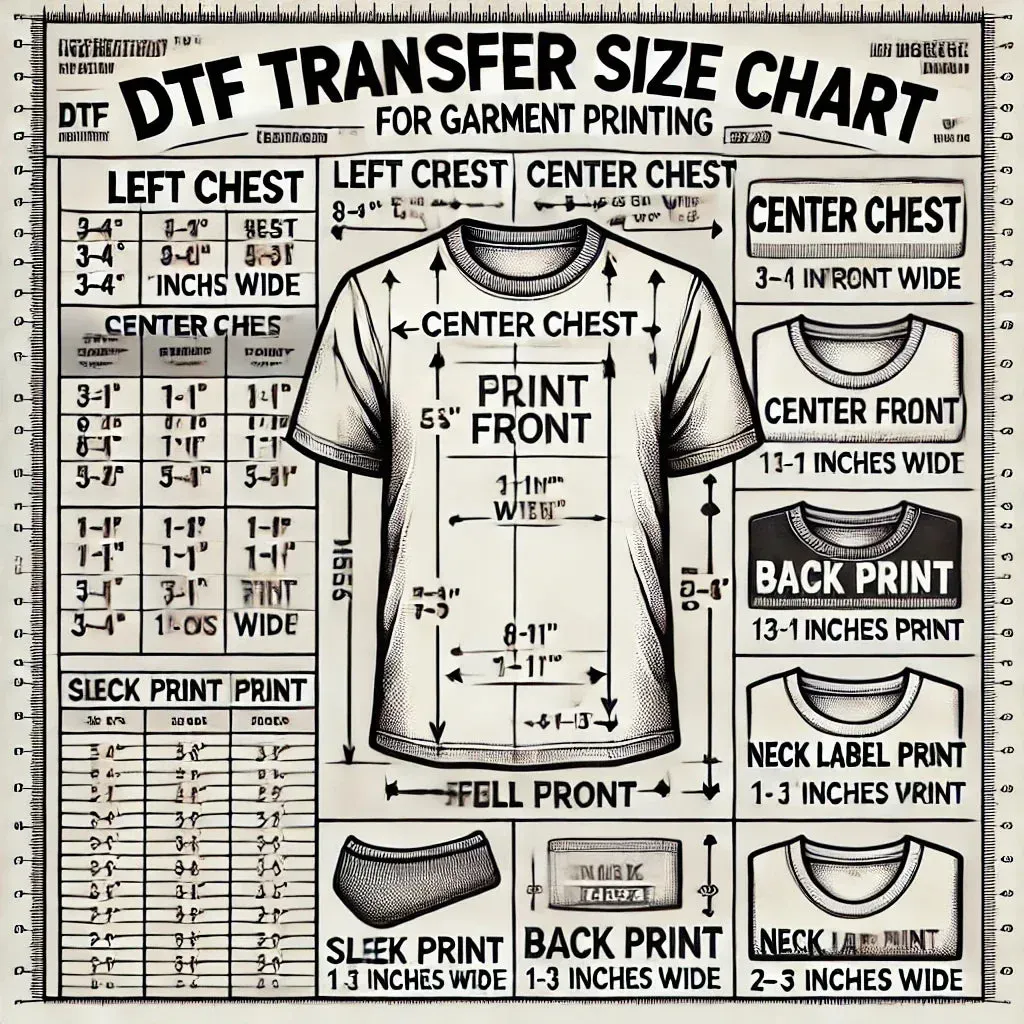

To frame the topic in broader terms, consider print area and garment dimensions as the compass for your project. The right footprint for a design depends on garment type, fabric weight, and viewing distance, and it is often guided by a print area chart rather than a single fixed number. Designers also talk about transfer scale, image size, and the relationship between edge details and material contours to ensure clarity on hoodies and tees alike. By thinking in terms of placement zones—center chest, upper back, or sleeve area—you can translate a concept into a scalable template for production. In practice, testing on sample garments remains essential to verify alignment across sizes and styles.

Understanding print area vs garment size in DTF transfer sizing

DTF transfer sizing starts with the print area relative to the garment size. By aligning the design width with the printable region, you ensure legibility and visual balance from a distance. Utilizing a DTF transfer sizing chart helps printers standardize how wide a design should be across different shirt sizes, so a small and a large garment don’t feel mismatched in scale. This approach also minimizes issues with seams, collars, and pockets that can distort the artwork if the transfer sits too close to edges.

To apply this concept effectively, start by identifying the maximum printable width for each garment size and type (T-shirts, hoodies, long-sleeve tees). A careful margin around the design—typically around 0.25–0.5 inches—preserves heat transfer tolerances and reduces edge flutter. Pair this with a practical DTF printing size guide to predict how the ink and film will interact with your fabric, ensuring the final result meets expectations across your product line.

DTF transfer by size: aligning designs for T-shirts and hoodies

DTF transfer by size is not a one-size-fits-all rule; it’s about choosing proportions that respect different garment silhouettes. The same artwork may appear larger on a hoodie due to a bulkier torso, while the same design on a tee could feel relatively smaller. This is where “how to choose transfer size for T-shirts” becomes practical: assess the chest width and torso length of the target garment and adjust until the design looks balanced and legible from arm’s length.

Consider the impact of garment type on readability and visual impact. A bold, high-contrast design can tolerate a larger width on hoodies where surface area is greater, whereas fine details may need a more restrained width on T-shirts to avoid crowding seams or losing crisp edges. Using a DTF transfer for hoodies with calculated widths ensures the design harmonizes with the garment’s proportions while preserving fidelity.

Using a DTF transfer sizing chart: practical steps for consistency

A DTF transfer sizing chart translates garment sizes into recommended design dimensions, creating consistency across batches. For example, it can suggest 6–8 inch widths for small shirts, 8–10 inches for medium, and 9–12 inches for large shirts, with hoodies often falling in the 9–12 inch range. Treat the chart as a baseline rather than a rigid rule, and adapt for shoulder width, chest circumference, and overall silhouette. This tool is central to building a reliable DTF printing workflow.

After selecting a baseline from the chart, test on a sample garment and adjust for brand differences and fabric weight. The DTF transfer size guide helps you tailor decisions to your specific artwork and production context, ensuring the final prints align with your brand standards. Always incorporate a physical test patch before committing to a full run so you can verify edge sharpness, color saturation, and edge bleed.

DTF transfer size guide and design considerations

Design considerations go beyond raw width. A proper DTF printing size guide accounts for line weight, color fills, and negative space, all of which affect perceived size and legibility. A highly detailed artwork might require a slightly larger transfer width to preserve fine lines, while a bold, chunky piece can scale well across a wider print area without losing impact. Remember that transfer film thickness and press temperature can subtly alter edge sharpness, so refer to the size guide and perform calibration tests.

Color contrast and material choice influence how large a design should be. On lighter fabrics, you may push for a larger width; on dark fabrics, you may reduce width to prevent color bleed or feathering. In practice, pairing the DTF transfer size guide with iterative tests—mock-ups on fabric that matches the final product—helps you lock in size decisions that keep fidelity intact across different fabrics and print runs.

Measuring, placing, and aligning for T-shirts and hoodies

Precise measurement starts with target garment size and the maximum printable width. Establish a margin around the design to accommodate heat transfer tolerances, and map artwork to a width that fits within those boundaries. For example, chest-width ranges commonly fall in the 8–12 inch zone for adult T-shirts, while hoodies may tolerate 9–12 inches. This method aligns with the principles of the DTF transfer sizing chart and helps you maintain consistent results across products.

Placement guidelines play a crucial role in perceived size. A chest- or center-front design typically sits 2–4 inches below the collarbone on T-shirts, with hoodies offering a similar vertical offset but more room for larger designs. For sleeve accents or pocket-area prints, keep widths around 4–6 inches. Consistent placement reinforces expected sizing and avoids visual misalignment at different garment angles.

From concept to final sizes: a workflow for reliable DTF printing

A systematic workflow helps you translate design concepts into correctly sized transfers. Start with the garment size range and correlate it to your DTF transfer sizing chart to establish a baseline width. Then review the artwork’s weight and detail; bold typography may allow a larger width, while intricate art may require careful adjustment.

Next, create digital mock-ups on the garment templates and test multiple widths to identify the best fit for your audience. Print physical tests on a sample garment to verify edge sharpness, color retention, and alignment, then gather feedback from stakeholders. Finally, finalize sizes for each garment type and build a small library of standard widths (e.g., 8-inch for certain tees, 9–12 inches for hoodies) to streamline future runs using the DTF transfer size guide.

Frequently Asked Questions

What is DTF transfer by size and why is it important for apparel printing?

DTF transfer by size defines choosing design dimensions that fit the garment’s printable area, balancing readability and proportion. Using a DTF transfer sizing chart helps standardize widths for different garments and avoids oversized or undersized designs that can cause misalignment or poor print quality.

How can I use the DTF transfer sizing chart to choose design dimensions for T-shirts and hoodies?

A DTF transfer sizing chart translates garment sizes into recommended design widths (e.g., 6–8 in for small, 8–10 in for medium, 9–12 in for large or hoodies). Start with the baseline, then tailor for your brand and print technique, and always verify with a test print on similar fabric.

What does a DTF transfer size guide cover, and how does it affect placement and readability across different garment types?

A DTF transfer size guide covers width, height, and placement considerations to preserve legibility across T-shirts, hoodies, and other garments. It helps you position the design (for example, chest or center-front on tees about 2–4 inches below the collar) while accounting for fabric weight and silhouette.

How do I choose transfer size for T-shirts using the DTF printing size guide?

Using a DTF printing size guide, determine the garment size, find the maximum printable width, and map your artwork within that boundary with a small margin (0.25–0.5 inches). Create digital and physical mock-ups, then run a test print to confirm edge quality and color fidelity.

What considerations should I keep in mind when applying DTF transfer for hoodies regarding size and proportion?

DTF transfer for hoodies often benefits from slightly larger designs to match the bulkier silhouette, with a common target around 9–12 inches wide. Ensure the design stays away from seams, aligns with the chest area, and check test prints to preserve proportion and edge clarity on thicker fabrics.

What steps should I take to measure and verify the right DTF transfer size for production using a sizing chart and test prints?

Start by selecting the target garment size and consult the DTF transfer sizing chart for a baseline width. Measure the max printable area, place the design with a margin, create mock-ups, and run physical tests on similar fabric. Gather feedback, then finalize the size for each garment type to ensure consistency.

| Aspect | Key Points |

|---|---|

| What is DTF transfer by size? | DTF transfer by size is a foundational concept for anyone printing designs on apparel; getting the right transfer size matters to avoid overwhelming or diluting the design. |

| Print area vs garment size | Start with the maximum printable area. For standard adult T‑shirts, chest width is typically 8–12 inches; hoodies are similar or larger. The goal is a design that fits within the printable region and remains legible. |

| DTF transfer sizing chart | A sizing chart translates garment sizes into recommended design dimensions. Typical guidance: S 6–8 in; M 8–10 in; L 9–12 in; hoodies 9–12 in. It’s a guide, not a rigid rule, accounting for shoulder width, chest circumference, and silhouette. |

| DTF transfer size guide and design considerations | Consider garment brand differences, fabric weight, and the level of detail. Very detailed artwork may require a larger design, but avoid crowding seams. Color contrast and line thickness affect perceived size; start with a baseline and test. |

| How to measure for the right transfer size | 1) Determine the target garment size. 2) Establish the maximum printable width. 3) Map artwork with a 0.25–0.5 inch margin. 4) Consider the height relative to torso. 5) Run a test print on a sample garment. |

| Print placement guidelines | T-shirts: chest or center-front about 2–4 inches below the collarbone. Hoodies: chest or upper abdomen. Sleeve or pocket designs: around 4–6 inches. Placement affects perceived size. |

| Design details and readability | Balance line weights, color fills, and negative space. Bold designs scale well; fine lines may blur. Transfers can alter edges at high temperatures or with thick films; always test print. |

| What to do about different garment types | T-shirts: 8–12 inch chest widths. Hoodies: 9–12 inch width. Long-sleeve/perf fabrics: widths ~8–10 inches. Youth garments: scale down proportionally. |

| Step-by-step process to pick the right size | 1) Start with the garment size range and baseline width from the chart. 2) Review the artwork for impact and readability. 3) Create a mock-up on a digital template. 4) Print a physical test. 5) Gather feedback. 6) Finalize the size for each garment type. |

Summary

DTF transfer by size is a foundational consideration for anyone printing designs on apparel. It guides how designs fit on different garments and at different viewing distances, helping ensure legibility and visual balance across T-shirts, hoodies, and youth pieces. By using a sizing chart and a careful measurement process, you can maintain consistency across batches while preserving brand integrity. A thoughtful size strategy reduces misprints and improves overall impact, making DTF transfers more efficient and predictable from concept to final product.