DTF Gangsheet Builder is redefining how shops approach textile production in the fast-paced world of garment decoration, delivering a smarter, more accessible path from concept to finished piece while inviting designers, production managers, and operators to rethink every step of the workflow. By focusing on layout efficiency, precise alignment, automated validation, and intelligent error checking, this tool brings clarity to planning and helps teams align on expectations long before ink meets fabric, avoiding costly reworks and downstream bottlenecks. It enables packing more designs into a single print run while preserving fabric integrity and color fidelity, dramatically reducing waste, minimizing setup time, and shortening lead times without compromising the customer experience. The result is a smoother digital textile workflow that untangles complex color management, standardizes color profiles, and accelerates the path from artwork to production, delivering consistent results across batches and garments. For studios and shops of any size, the system offers a practical route to faster, smarter textile prints, easier job tracking, and reliable on-time delivery, making it a core asset in modern print production pipelines.

From another perspective, this workflow technology can be seen as a sheet-management and production-planning tool that coordinates multi-design orders by optimizing how artwork is arranged on the print sheet. It functions as a print shop workflow optimizer, linking design files, color management steps, and material considerations to reduce waste and shorten turnaround times. Seen in terms of digital textile production, the approach aligns with modern notions of batch printing, color fidelity, and process automation, supporting operators with clearer visibility and predictable outcomes. In short, the concept translates to a scalable system for garment decoration that bridges creativity and manufacturing, improving efficiency without compromising quality.

DTF Gangsheet Builder: Maximizing Output in Textile Printing

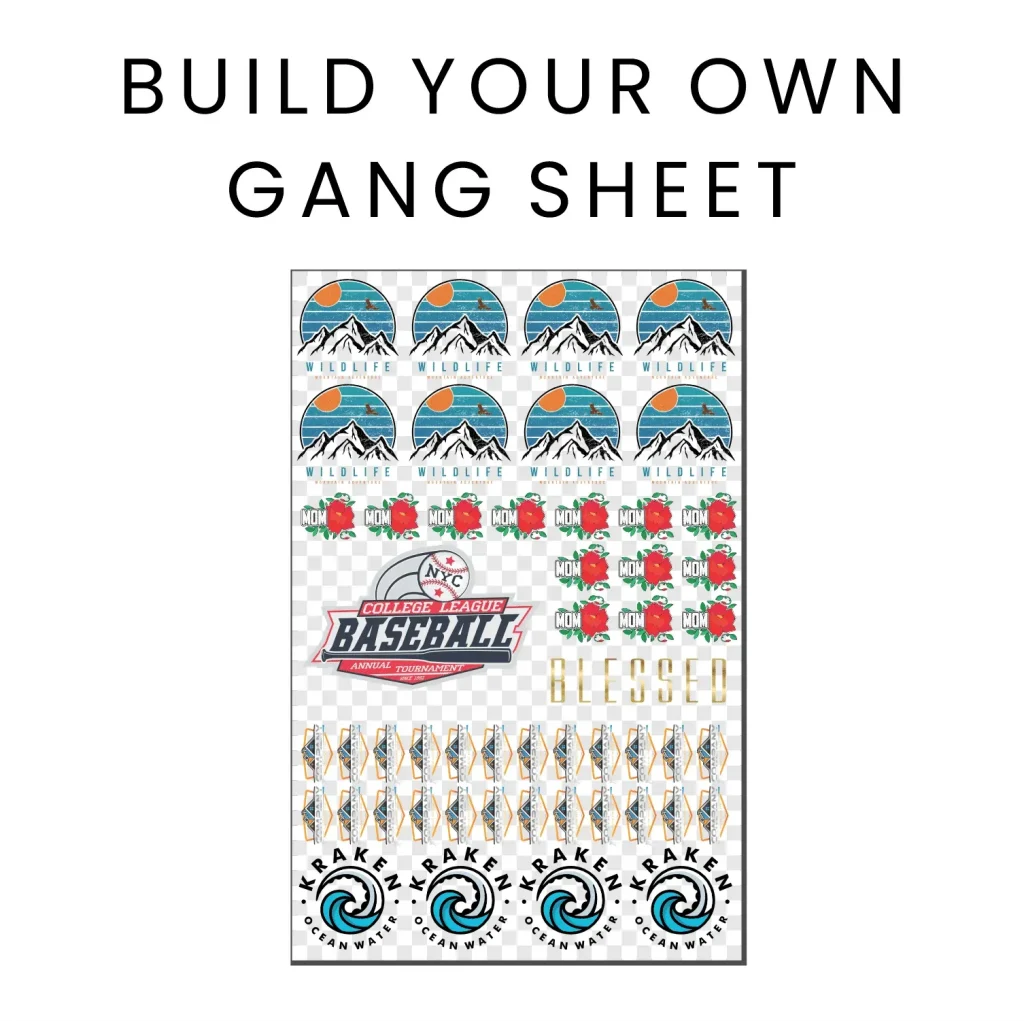

The DTF Gangsheet Builder lets shops pack more designs into a single print run without compromising image quality or fabric integrity. In DTF printing, gangsheet printing refers to arranging multiple designs on one sheet to maximize throughput. This approach speeds up production and reduces the queue of orders, helping teams meet tight deadlines while preserving print quality across textiles.

With a focus on a smooth digital textile workflow, the builder optimizes layout by blending color profiles and margins. It also minimizes material waste by efficient nesting and automated spacing, contributing to higher print production efficiency across the board.

Improving Print Production Efficiency Through Strategic Gangsheet Layouts

Strategic gangsheet layouts transform the way shops approach textile printing by balancing design density and color management. The DTF Gangsheet Builder analyzes designs for printable areas, color count, and fabric constraints, producing layouts that maximize printed images per sheet. This reduces setup time and the number of reprints in DTF printing.

By streamlining color management and print sequencing, shops can push more orders through with fewer bottlenecks. The result is a measurable lift in print production efficiency, with a smoother digital textile workflow from design to finished garment.

Enhancing Color Management and Image Quality in Textile Printing

Color accuracy is critical when packing multiple designs into one gangsheet. The builder leverages color profiles, ICC management, and consistent seps to maintain uniform hues across all designs in DTF printing. This is essential for textile printing where fabric variability can affect color rendition.

Quality preservation remains a priority as the gangsheet grows. The DTF Gangsheet Builder helps preserve image sharpness, smooth gradients, and faithful reproduction on various fabrics, ensuring that print quality stays high even when workflows push multiple designs simultaneously within a single run.

Streamlining the Digital Textile Workflow from Concept to Garment

From initial design concepts to production-ready files, the digital textile workflow benefits from a cohesive gangsheet strategy. The builder consolidates files, aligns color standards, and outputs print-ready gang sheets, shortening iteration cycles and reducing design handoffs.

Shops can collaborate more effectively between design, prepress, and production teams. With fewer back-and-forth changes and faster approval cycles, the path from concept to garment becomes more predictable, supporting on-time delivery in a fast paced market.

Reducing Waste and Material Costs with Efficient Gangsheet Strategy

Efficient nesting of designs minimizes fabric waste and scrap. By optimizing margins, seam allowances, and waste gaps, the same sheet yields more garments per run, lowering material costs per piece in textile printing and DTF printing alike.

In addition to material savings, the streamlined process reduces dye usage and energy consumption due to fewer print passes and optimized head movements. The overall impact strengthens sustainability and improves print production efficiency across the workflow.

Practical Steps to Implement DTF Gangsheet Builder in Your Studio

Start by auditing your current workflow to identify bottlenecks in queue times, color management, and file handoffs. Gather your designs, fonts, and color profiles, then set up a pilot gangsheet project to test layout logic and print quality across fabrics used in your line for textile printing.

Next, adopt templates and automation within the DTF Gangsheet Builder to standardize spacing, margins, and color separation. Run test prints, calibrate color, and measure key metrics like print production efficiency, waste rate, and throughput to guide full scale rollout in your digital textile workflow.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve DTF printing and print production efficiency?

The DTF Gangsheet Builder is a layout tool that packs multiple designs into a single gangsheet, optimizing space and reducing setup time in DTF printing. By maximizing print yield and streamlining alignment, it enhances print production efficiency, speeds up orders, and minimizes waste without compromising image quality.

How does gangsheet printing with the DTF Gangsheet Builder optimize textile printing layouts?

Gangsheet printing with the DTF Gangsheet Builder optimizes layouts by efficiently arranging designs to maximize fabric usage, reduce material waste, and maintain consistent color across all panels. This approach also simplifies color management during textile printing.

In what ways does the DTF Gangsheet Builder support color accuracy and image quality in textile printing?

The tool supports centralized color management and precise image placement, helping maintain color accuracy and high image quality across all designs on a single gangsheet, while protecting fabric integrity during textile printing.

How can the DTF Gangsheet Builder streamline the digital textile workflow from design to finished garment?

The DTF Gangsheet Builder integrates design layouts into the digital textile workflow, reducing back-and-forth approvals and manual adjustments. This speeds up concept-to-print cycles and creates a smoother transition from design to finished garment.

What features of the DTF Gangsheet Builder help meet tight deadlines in busy print production environments?

Key features include quick layout previews, automated validation, and batch packing of designs into gang sheets, all of which accelerate proofing and production in DTF printing, helping teams meet tight deadlines.

How does using the DTF Gangsheet Builder reduce material waste and improve shop throughput in DTF printing?

By optimizing sheet utilization and minimizing misprints, the DTF Gangsheet Builder lowers material waste while boosting throughput. The result is faster print runs, better cost efficiency, and a smoother digital textile workflow from start to finish.

| Aspect | Key Points | Benefits / Impacts |

|---|---|---|

| What it is | DTF Gangsheet Builder enables packing more designs into a single print run. | Maximizes production capacity and optimizes use of the printer. |

| Primary goal | Increase design density per gangsheet without sacrificing image quality, color accuracy, or fabric integrity. | Faster outputs while maintaining print standards. |

| Efficiency | Streamlines textile workflows and reduces the queue of pending orders. | Quicker turnaround times and improved throughput. |

| Waste & color management | Reduces material waste; simplifies color management. | Cost savings and more consistent colors across batches. |

| Workflow impact | Smooth digital textile workflow from concept to finished garment. | Lower risk of delays; easier project management. |

| Outcome | Faster, smarter textile prints that meet tight deadlines and high-quality standards. | Improved customer satisfaction and production reliability. |

Summary

Conclusion: DTF Gangsheet Builder reshapes how textile shops approach production by combining speed with accuracy to deliver high-quality prints more quickly. Packing multiple designs into a single print run while preserving image quality, color accuracy, and fabric integrity reduces material waste and simplifies color management, creating a smoother digital textile workflow from concept to finished garment. This guide highlights how to leverage the DTF Gangsheet Builder to achieve faster, smarter textile prints that meet tight deadlines and uphold high standards of quality and consistency.