DTF transfer size governs legibility, color fidelity, and the overall impact a design has on fabric. DTF transfer size guidelines help you decide how much of the artwork shows, how details translate, and how you set the print area. A thoughtful approach can prevent distortion and misalignment across garments and substrates. DTF image resolution per size should guide file preparation and downscaling to preserve edge clarity. With these considerations, you can optimize readability, color density, and production throughput across a range of shirts and hoodies.

In other words, the dimensions you choose for each transfer stage shape how the artwork interacts with fabric, the viewer, and the finished garment. Think of this as print area planning: selecting space for the design, balancing contrast, and preserving legibility across shirt sizes. From a semantic angle, you can discuss artwork scaling, asset reuse, and how substrate compatibility shapes the final look. LSI-style terms like print footprint, scaling rules, and color density management help capture related ideas without repetitive phrasing. By aligning these size-aware concepts with your production workflow, you ensure consistent visual impact from a small logo to a full-back graphic.

DTF Transfer Size Fundamentals: Defining Print Area for Impact

When you choose a print area, you aren’t just selecting a dimension—you’re setting the stage for legibility, color fidelity, and how the design sits on the garment. This is where DTF transfer size guidelines begin to shape decisions, from the most visible front‑and‑center logos to more intricate back designs. Understanding the impact of size upfront helps you plan artwork with the right balance of detail and readability across varieties of garments.

In practice, size decisions ripple through every step of the workflow—art preparation, print area selection, bleed and safe margins, and post‑press checks. By anchoring your process to a clear understanding of DTF transfer size, you can reduce misalignment, distortion, and color issues, ensuring predictable results from the first test to the final production run.

DTF Printing Size Standards: Building a Consistent Size Ladder for All Garments

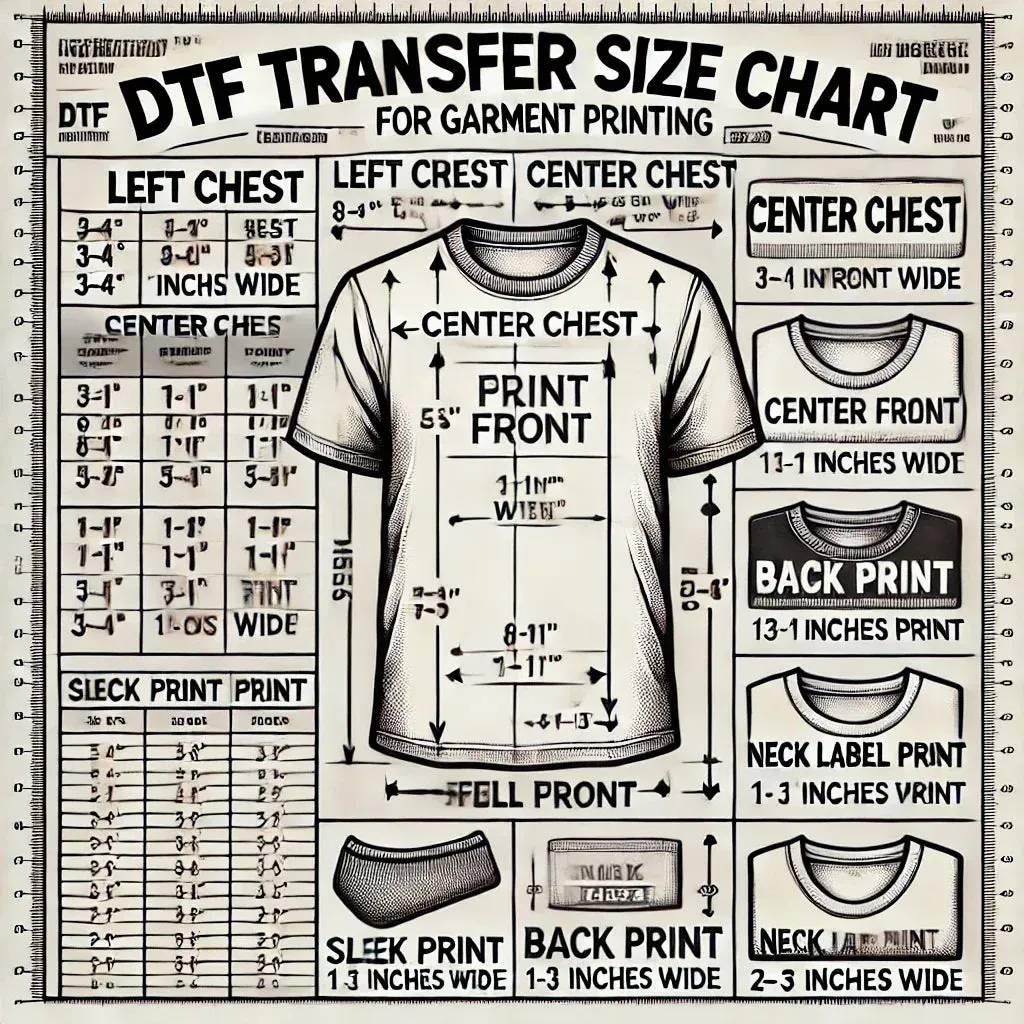

Understanding DTF printing size standards means recognizing the typical print areas used for different garments and applications. For casual tees, chest logos often land in the 2×3 to 4×6 inch range, while full‑back designs or sleeves can reach 8×10 to 12×14 inches or larger. Although there is no universal standard, many shops rely on tiered guidelines to keep outputs consistent across product lines and sizes.

A practical approach is to build a size ladder within your prepress workflow. Establish core targets such as 2×3 (small), 4×6 (medium), and 8×10 (large), then test artwork scaling between sizes. This ladder helps you anticipate how designs perform when applied to different garment dimensions and ensures consistency across collections, regardless of the garment color or texture.

Mapping Designs to Print Areas: From Small Logos to Full‑Back Art with Size‑Aware Guidelines

Effective mapping starts with a garment assessment and a clear plan for how the artwork will interact with the target print area. Following DTF transfer size guidelines, small prints should avoid ultra‑fine details that blur after transfer, while larger prints benefit from stronger contrast and more robust color blocks to preserve readability.

Practical steps include aligning critical elements away from edges, incorporating bleed, and testing alignment at each target size. By adapting typography, line work, and color blocks for each size, you ensure that a simple chest logo remains crisp and legible, while a full‑back design delivers impact without crowding seams or margins.

DTF Image Resolution per Size: Preserving Detail and Clarity Across Scales

A cornerstone of successful DTF is matching image resolution to the final print size. The general rule is to start with high‑resolution artwork at the largest intended size and downsize for smaller formats. Following the principle of DTF image resolution per size helps maintain edge clarity and avoid pixelation when scaling down.

Key considerations include using vector graphics for logos and type to preserve crisp edges, and ensuring raster assets are prepared at or above the largest planned size. When scaling down, verify that text remains legible and color blocks retain their weight, and manage color calibration to preserve the intended appearance across fabrics.

Designing for DTF Transfers: Typography, Color Blocks, and Safe Margins

Designing for DTF transfers requires planning for how text, lines, and color blocks will render after heat application. In line with Designing for DTF transfers, you should anticipate weight changes and avoid relying on hairline details that may disappear at smaller sizes. Bold, legible typography and robust line weights help translations stay readable across sizes.

Color strategy matters too: gradients can be tricky on film transfers, so flatter color blocks or stepped tones are often more reliable for smaller prints. Always include safe margins and bleed, and adjust the color density to maintain the artwork’s visual balance when it’s scaled up or down for different garment dimensions.

Prepress, Substrates, and Production Alignment: Ensuring Size‑Ready Output

A robust prepress workflow aligns file preparation with production reality, ensuring the DTF transfer size matches the planned print areas on every garment. This includes documenting target sizes, delivering artwork with proper bleed and color profiles, and performing test transfers to verify alignment and color density.

Substrate considerations—such as fabric type, weight, and texture—play a critical role in how size decisions translate to final results. White underbases on dark fabrics, fabric stretch, and dye uptake all influence the effective print area and perceived size, so incorporate DTF substrate size compatibility into your planning and validation steps to maintain consistency across different garment types.

Frequently Asked Questions

What are DTF transfer size guidelines and why are they important for consistent results?

DTF transfer size guidelines shape how you plan print areas from chest to back, balancing legibility, color density, and fabric constraints. Build a size ladder with core targets like 2×3, 4×6, and 8×10, and run test prints to verify readability and alignment across sizes. Include adequate bleed and safe margins to accommodate heat press shifts and edge cropping.

How do DTF printing size standards influence artwork planning from small logos to full back designs?

DTF printing size standards help you set target sizes early and check legibility at each scale. Start with core sizes such as 2×3, 4×6, and 8×10, preserve aspect ratio, and test across garment types to ensure consistent impact and color balance.

What should you focus on when designing for DTF transfers to maintain readability across sizes?

Prioritize bold typography and clean line work to prevent loss of detail at smaller sizes. Design at the largest anticipated size first, then create smaller downsize variants and verify legibility. Ensure critical elements stay within safe margins and account for substrate differences.

Why is DTF image resolution per size critical for crisp transfers?

Match image resolution to the final print size, aiming for 300 DPI as a baseline and up to 600 DPI when supported. Use vector for logos and text to preserve edges, and keep raster artwork at or above the largest planned size before scaling. Calibrate color management to preserve density across sizes.

How does DTF substrate size compatibility affect print area decisions across fabrics?

Fabric type and weave influence ink absorption, opacity, and edge sharpness, so print areas may need adjustments by size. On dark fabrics, an underbase may be required to preserve contrast, which can alter the effective print area. Consider fabric weight, stretch, and texture when planning sizes.

What is a practical workflow for applying DTF transfer size guidelines across multiple sizes?

Create a master artwork at the largest expected size, for example 12×14 inches. Generate downsize variants (8×10, 4×6, 2×3) and verify legibility at each size. Preserve aspect ratio, maintain bleed and safe margins, and run test prints to confirm alignment and color density on the chosen fabric. This aligns with DTF printing size standards.

| Aspect | Key Points |

|---|---|

| Introduction | DTF transfer size is a governing factor that affects legibility, color fidelity, and overall impact on the garment. It determines how much of the design will be visible and how artwork interacts with shirt or hoodie dimensions, guiding planning from design to production to ensure graphics look great at every size. |

| DTF printing size standards and typical print areas | Common ranges: chest sizes typically 2×3 to 4×6 inches; back or larger designs often 8×10 to 12×14 inches or larger. There is no universal standard, so many shops use tiered guidelines and a size ladder (2×3, 4×6, 8×10) to verify legibility and impact at each target size. |

| Guidelines by size: mapping designs to print areas | Small prints should avoid relying on fine details that may blur after transfer. Larger prints require stronger contrast and more robust color blocks to maintain readability. Practical guidelines: Text and fine lines: increase font weight; convert small text to bold; test readability at the smallest target size. Color blocks vs. gradients: use flatter color blocks for small sizes; interpolate gradient-like effects with a few stepped tones. Bleed and safe margins: include bleed; keep critical elements like logos and text at least 1/8 to 1/4 inch from the edge. Backing and substrate: dark fabrics may require white underbases to preserve contrast; consider substrate constraints when deciding print areas. |

| Resolution and image quality: the role of DTF image resolution per size | High-resolution art at the largest intended size, then downsize for smaller formats. Target resolution: 300 DPI at final print size; 600 DPI possible but 300 DPI is a reliable baseline. Vector vs. raster: use vector for logos and type; raster images should be prepared at or above the largest planned size. Text and line work: ensure strokes are thick enough to stay legible after transfer. Color accuracy: calibrate colors and manage color weight when scaling from large to small formats. |

| Designing for multiple sizes: practical workflows and reuse of assets | Design a master artwork at the largest size and create scaled-down variants for smaller sizes. Start with a large canvas (e.g., 12×14 inches); build a strong focal point and balanced negative space. Create downscaled variants (e.g., 8×10, 4×6, 2×3) and verify legibility; adjust font sizes, line thickness, and color density for each size. Maintain aspect ratio to avoid distortion and keep the transfer’s print area within safe margins. Test prints on the same fabric to compare color density and detail, making iterative adjustments as needed. |

| Substrates and how they affect size decisions | Fabric choice influences appearance at different sizes (cotton vs blends). Cotton fabrics behave differently under heat, affecting color saturation and edge sharpness. Fabric weight and texture can require different heat or dwell times. White underbase on dark fabrics can improve opacity and contrast, influencing the effective print area. Stretch and recovery: fabrics may stretch during wear, slightly altering perceived size; design with margins to accommodate stretch. |

| Practical prepress steps: aligning size with production | Confirm target print areas for each product, document chest/sleeve/back specs. Prepare art files with appropriate bleed, safe margins, and color profiles; use vector files for logos and high-resolution raster images for photos. Run test prints to verify alignment, color density, and edge sharpness. Align printing and heat settings (time, temperature, pressure) to the fabric to ensure consistency across sizes. |

| Common pitfalls and how to avoid them | Oversizing beyond the garment’s print area can cause wrapping or distortion. Under-resolving: upscaling low-res art leads to pixelation. Inconsistent color: substrate variations can shift color; implement consistent color management. Inaccurate bleed: missing bleed can cause white edges after heat application; provide ample bleed and safe margins. |

| Case study in practice | Two-product line: a small chest logo (3×3 inches) and a full-back design (12×14 inches). Start with a master file at 12×14 inches, then create scaled-down variants (3×3). Convert text to outlines for stability and validate color saturation at each size through test prints. |

Summary

DTF transfer size sits at the heart of a successful design-to-print workflow, guiding decisions from art creation to final application. By planning for DTF transfer size early, designers can maintain readability, color fidelity, and a cohesive look across garments. A size-aware approach reduces iterations and ensures consistent results, whether the design is a small chest logo or a bold full-back print. With clear DTF transfer size guidelines and careful attention to resolution, substrates, and prepress steps, studios can deliver professional graphics that look great on any size.