DTF Transfer by Size is a crucial consideration for those in the custom apparel industry looking to leverage the benefits of Direct-to-Film printing. As this innovative technology offers unparalleled quality and vibrant colors, it’s essential for designers to refine their approaches to suit varying garment sizes. The ability to tailor DTF transfers effectively ensures that every piece of clothing not only looks fantastic but fits perfectly as well. By adjusting the scale of graphics for each size, designers can create stunning, personalized pieces that stand out in today’s crowded marketplace. Whether you’re crafting children’s clothing or adult apparel, mastering the art of DTF transfer by size can set your designs apart, making them not just wearable art but also a customer favorite.

When discussing DTF Transfer by Size, one may also refer to this process as adapting Direct-to-Film prints for various dimensions or garment proportions. This method, part of the increasingly popular realm of customized printing, emphasizes the importance of scalability in design, particularly for businesses focused on unique clothing solutions. By using relevant customization software, designers can manipulate graphical elements to fit different apparel sizes seamlessly. The versatility of DTF printing technologies allows for innovation in creating size-specific designs that cater to diverse consumer needs, further driving demand in the bespoke fashion market. Consequently, understanding the nuances of tailoring graphics by size not only enhances product quality but also boosts customer satisfaction.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing has emerged as a groundbreaking technique in the world of custom apparel. This innovative process enables designers to print high-resolution images onto a specialized film, which is then heat-pressed onto fabrics. DTF printing stands apart from traditional methods due to its remarkable ability to produce vivid colors and intricate designs that adhere to a range of materials. As consumers increasingly seek personalized apparel, understanding the fundamentals of DTF printing becomes essential for anyone working in the garment industry.

The versatility of DTF printing extends beyond the aesthetics; it also boasts impressive durability. The prints produced are resistant to fading, cracking, or peeling, ensuring that the designs maintain their integrity, even after multiple washes. This resilience is particularly appealing to businesses aiming to deliver quality products to their customers. Moreover, DTF transfers can be applied to various fabrics, from cotton to blends, making it a popular choice among apparel makers.

DTF Transfer by Size: Importance in Customization

As demand for unique and personalized clothing rises, the significance of tailoring DTF transfers by size cannot be overstated. Implementing size-adjusted designs allows consumers to experience a perfect fit and a professional finish, which is crucial in retaining customer satisfaction. In a marketplace saturated with options, providing apparel that not only looks good but also fits well can set businesses apart from their competitors. Therefore, understanding how to customize DTF transfers effectively for size variations in garments is an essential skill for designers.

Furthermore, the customization aspect of DTF transfer by size opens up opportunities for brands to cater to diverse customer needs, from children’s sizes to a range of adult fits. This adaptability not only enhances customer loyalty but also boosts sales, as consumers are more likely to return for additional purchases if they feel positively about their initial experience. In essence, mastering the art of DTF transfer sizing is indispensable for any business aspiring to thrive in the ever-evolving realm of custom apparel.

Scaling Graphics for Perfect Fit

Scaling graphics is a fundamental step that designers must master when working with DTF transfers, especially considering the variety of sizes in the apparel market. Utilizing vector graphics is highly advantageous, as these images can be resized without losing their quality. For software users like Adobe Illustrator, designing with vectors allows for seamless adjustments across different sizes of garments, whether it be for small children’s t-shirts or large adult hoodies. By keeping flexibility in mind while designing, creators can ensure that their graphics retain their vibrancy and clarity, regardless of the size.

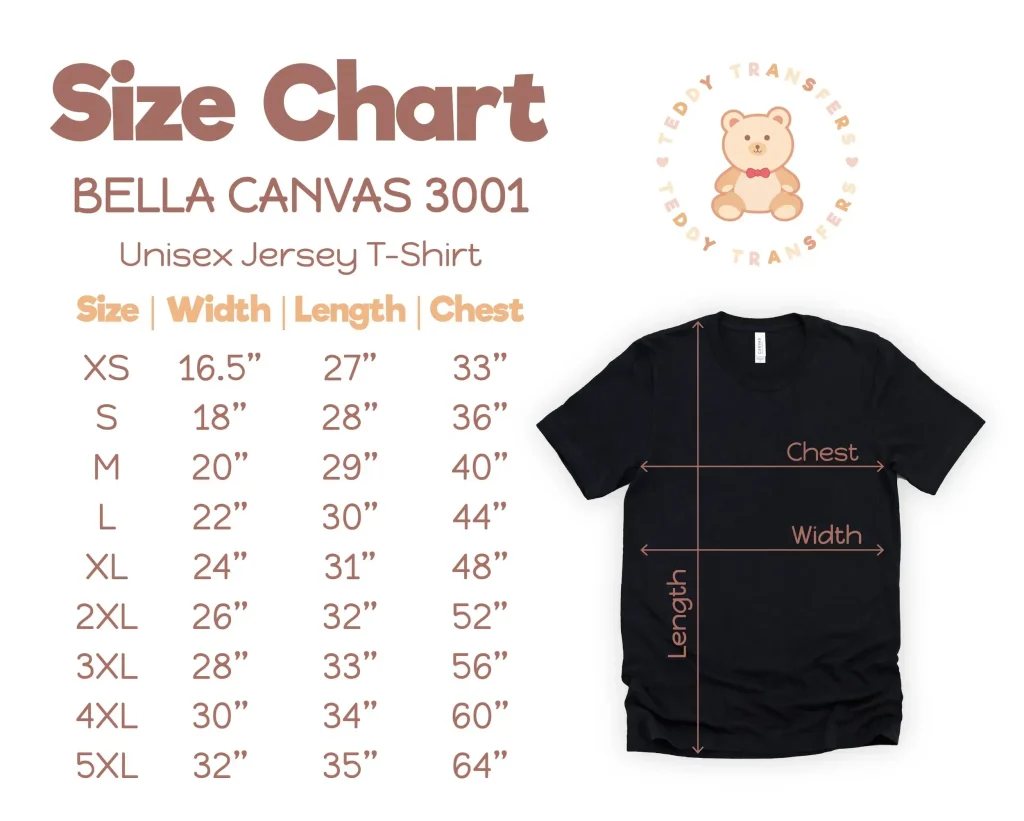

Additionally, understanding the specific dimensions required for each garment size is crucial. This foresight enables designers to create designs that not only fit well but also maintain their integrity when adapted for various size adjustments. Rigorous preparation and attention to detail in the initial design phase lead to a smoother process, allowing brands to swiftly meet consumer demands, whether they’re designing for a large batch order or a one-off custom piece.

The Role of Material in DTF Printing

Material choice plays a pivotal role in the outcome of DTF printed designs. Each type of fabric interacts differently with the DTF printing process. For instance, cotton fabrics typically provide excellent adhesion, resulting in vibrant and long-lasting prints. In contrast, DTF transfers on polyester may require more attention to heat settings to avoid damaging the fabric. Understanding how various materials will respond to DTF printing is essential for designers who want to ensure high-quality results.

Moreover, the advancement in DTF technology has led to the development of specialized films designed for different fabric types. These innovations improve adhesion and enhance the overall quality of the prints, ensuring that the final product meets consumer expectations. By choosing the right combination of fabric andD film technology, businesses can significantly elevate the quality of their custom apparel offerings.

Leveraging Customization Software for DTF Printing

Modern advancements in technology have resulted in the creation of powerful customization software that streamlines the DTF printing process. These platforms enable designers to automatically adjust the size and placement of graphics based on the selected garment type, reducing the likelihood of errors and increasing efficiency. Moreover, integrating such software with eCommerce platforms allows end-users to visualize their designs, ensuring they achieve the desired look before finalizing their orders.

Utilizing these automation tools not only enhances the designer’s workflow but also significantly improves the customer experience. Consumers appreciate having the ability to customize their apparel, which leads to greater satisfaction and higher conversion rates for businesses. By leveraging these software solutions, designers can remain competitive in a fast-paced market while providing an avenue for personalized creativity.

Trends Shaping the Future of DTF Printing

The landscape of DTF printing is rapidly evolving, driven by market trends that emphasize customization and on-demand production. As consumers increasingly demand unique apparel options, businesses are compelled to innovate continually. The incorporation of eco-friendly materials and advanced printing technologies is a growing trend within the industry, ensuring that brands can produce high-quality products while adhering to environmental standards.

Moreover, the focus on user-friendly software tools is expanding the scope of who can engage in DTF printing, opening doors for small businesses and independent creators. As understanding of DTF printing grows, so too does the market potential for those willing to embrace these changes. With continued investment in training and technology, the future of DTF printing promises significant opportunities for creative entrepreneurs ready to innovate in the custom apparel sector.

Frequently Asked Questions

What is DTF Transfer by Size and why is it important for custom apparel?

DTF Transfer by Size refers to the process of tailoring Direct-to-Film (DTF) transfers according to the dimensions of various garment sizes. This adaptation is crucial for custom apparel as it ensures that designs are perfectly scaled for small, medium, large, or extra-large clothing, thereby enhancing the overall fit and appearance. Properly sized transfers not only improve customer satisfaction but also contribute to professional-quality finishes.

How can I scale graphics effectively for DTF printing?

To scale graphics for DTF printing effectively, designers should use vector graphics, which maintain their quality regardless of size adjustments. Programs like Adobe Illustrator allow for easy resizing, enabling designers to create artwork that is flexible and can be tailored for different garment sizes. Always determine the exact dimensions needed for each size before starting your design to streamline the resizing process.

What materials work best for DTF transfers by size?

The best materials for DTF transfers include cotton, polyester, and blends of the two. Cotton provides excellent adhesion and vibrancy, while polyester requires careful heat settings to avoid damage. Blended fabrics often yield the best results, leveraging the softness of cotton with the durability of polyester. Choosing the right fabric is essential for achieving high-quality, durable prints.

Why is testing size options important in DTF printing?

Testing size options in DTF printing is important because it allows designers to see how different sizes affect the look and fit of the printed design. By creating sample prints for various sizes, such as small, medium, and large, designers can assess how well their graphics translate onto different fabrics and ensure that the final product meets customer expectations.

What role does customization software play in DTF Transfer by Size?

Customization software plays a significant role in DTF Transfer by Size by enabling designers to easily adjust the size and placement of prints based on customer specifications. Many platforms offer automation features that integrate with eCommerce solutions, allowing users to visualize their designs on the selected garment size before finalizing an order. This not only enhances user experience but also increases conversion rates.

How do market trends impact the use of DTF transfers for multiple sizes?

Market trends significantly impact the use of DTF transfers for multiple sizes as the demand for personalized and on-demand apparel continues to grow. Businesses that successfully implement DTF printing to create versatile designs can capitalize on this trend. Staying ahead by incorporating advancements in printing technologies and user-friendly customization tools can provide a competitive edge in the expanding market.

| Key Aspects | Details |

|---|---|

| What Are DTF Transfers? | DTF involves printing designs on a film, which is transferred onto fabric via heat. Notable for high-resolution, durability, and versatility. |

| Tailoring Designs for Different Sizes | Designers must take into account scaling graphics and testing size options to ensure proper fit and aesthetics. |

| Materials Considerations | Cotton, polyester, and blends react differently to DTF; hence choosing the correct fabric is crucial for optimal results. |

| Customization Software and Automation | Digital tools simplify size adjustments and enhance customer experience through user-friendly design manipulation. |

| Market Trends and Future Prospects | The market is growing, driven by customization demand, necessitating ongoing adaptations from designers and businesses. |

Summary

DTF Transfer by Size is critical for successfully adapting designs across various garment sizes in the apparel printing industry. By mastering the principles of DTF transfers, designers can produce high-quality, vibrant prints that cater to the growing demand for personalized clothing. Understanding how to scale graphics, the importance of thorough testing, and the nuances of different fabric types greatly enhance the final product’s fit and appearance. As businesses continue to navigate market trends toward customization, employing the right software and automation tools can streamline the design process and improve customer satisfaction. Ultimately, adaptability in DTF transfer techniques will ensure that designers remain competitive in an ever-evolving landscape, creating pieces that resonate with their target audience.