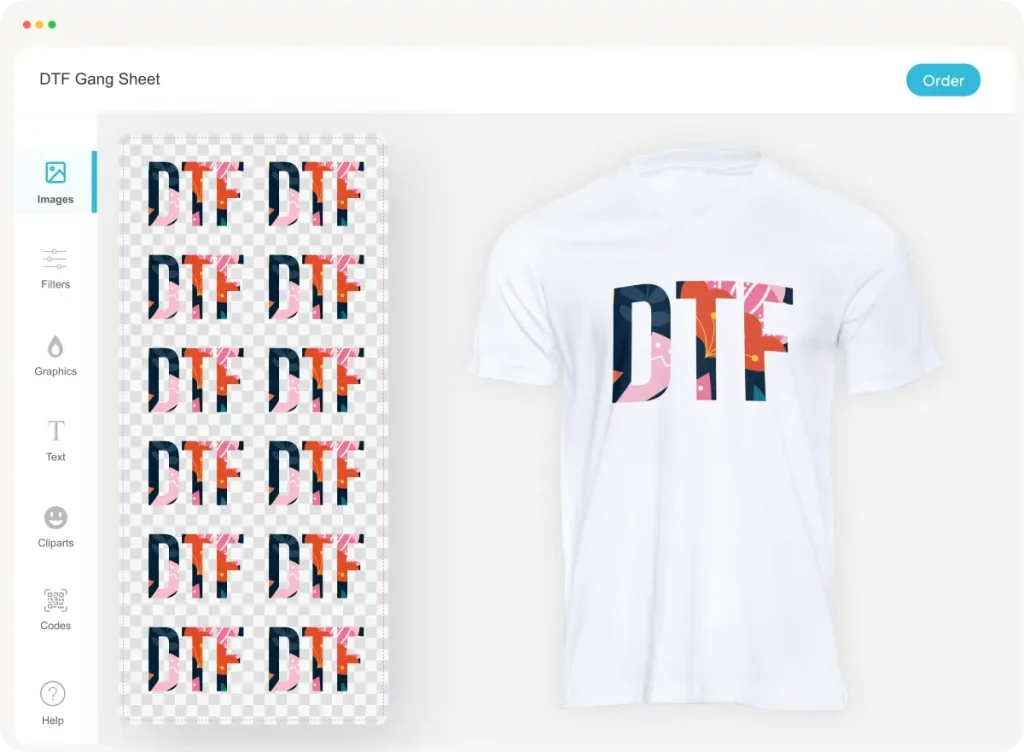

The DTF Gangsheet Builder has emerged as a revolutionary tool in the world of DTF printing, allowing professionals to streamline their workflow and enhance production efficiency. This innovative technology empowers users to arrange multiple designs on a single gangsheet, providing a practical solution for managing custom orders while minimizing material waste. In this guide, we’ll delve into a detailed gangsheet tutorial that covers everything from design preparation to the heat transfer process, ensuring you have all the tools at your disposal to excel in DTF printing techniques. Whether you’re a seasoned printer or new to applying adhesive powder, understanding how to use the DTF Builder can significantly impact your output quality and speed. Join us as we explore the myriad advantages of the DTF Gangsheet Builder and unlock the potential of your printing business.

The DTF Gangsheet Builder, also known as the Direct-to-Film sheet creator, is a game-changer for those involved in apparel decoration. This cutting-edge tool is designed for optimizing the DTF printing process, enabling users to print an array of designs on a single film sheet. By efficiently arranging graphics, users can maximize printer output while ensuring high-quality applications on various textiles. Additionally, mastering the techniques of this builder, from adhesive powder application to heat transfer methods, will ensure that garments proudly feature vibrant and long-lasting graphics. In this tutorial, we’ll reveal essential insights and tips to help you tap into the full potential of this advanced printing method.

Understanding DTF Printing Techniques

DTF printing, or Direct-to-Film printing, marks a revolutionary shift in the garment decoration industry. This technique involves transferring high-resolution designs onto a specialized film, followed by applying them directly to fabric using heat and pressure. What sets DTF printing apart is its ability to produce vibrant colors and detailed imagery, making it a preferred choice for custom printing on a wide range of textiles. As consumers demand more intricate designs, the DTF printing method rises to the occasion, showcasing its versatility and durability over traditional printing methods.

The DTF Gangsheet Builder plays a crucial role in enhancing the efficiency of the DTF printing process. By allowing multiple designs to be printed on a single sheet, users can significantly reduce waste and streamline their workflow. This technique not only saves time but also optimizes ink usage, making it an economically viable option for businesses looking to fulfill numerous orders without sacrificing quality. Mastering these DTF printing techniques ensures that creators can meet changing market demands where creativity and efficiency are paramount.

How to Use the DTF Gangsheet Builder Effectively

To achieve optimal results with the DTF Gangsheet Builder, users need to begin by preparing their designs meticulously. Utilizing graphic design software enables creators to manipulate and format their artwork accurately according to the gangsheet dimensions. High-resolution images in formats like PNG and JPG are recommended to maintain clarity and vibrancy during the printing process. Additionally, understanding how to leverage the DTF Builder’s features can further optimize the layout, ensuring each design is positioned strategically to maximize print space.

Once the designs are ready, engaging with the DTF Gangsheet Builder becomes a crucial step in your workflow. Properly utilizing printer settings, such as ink types and color profiles, is essential to ensure a successful printing outcome. This tool also allows users to combine various designs, potentially creating a diverse range of products from a single print run. Subsequently, following up with appropriate adhesive application and heat transfer techniques will solidify the final product’s quality, making it essential for creators to understand each component of the process.

The Importance of Applying Adhesive Powder

Applying adhesive powder is a pivotal step in the DTF printing process, ensuring that the stunning designs printed on film adhere securely to the fabric. After the film has been printed, an even layer of adhesive powder must be applied while the design is still wet. This crucial step binds the ink to the film, enabling it to withstand the heat transfer process. Without proper adhesive application, the vibrant colors and intricate designs may not withstand washing or wearing, leading to dissatisfaction among customers.

The technique of applying adhesive powder also requires precision. It’s important to ensure that the adhesive is evenly distributed and adequately melted during the heat transfer time. This creates a solid bond between the ink and fabric while enhancing the durability of the prints. Creators often experiment with different adhesive types to achieve optimal results, which further establishes the effectiveness of their DTF printing processes. Mastering adhesive application techniques can greatly contribute to the longevity of the printed designs.

Heat Transfer Techniques for DTF Printing

Heat transfer is a critical process in DTF printing, directly impacting the quality and durability of the final designs. By applying the gangsheet to the fabric with the correct amount of time and pressure, creators can ensure that the prints adhere properly. Each type of fabric may require different heat settings, so it is essential for printers to understand the characteristics of their materials. This knowledge not only enhances the finished product’s appearance but also ensures its longevity through multiple washes.

Moreover, investing in a reliable heat press machine is crucial for achieving consistent results. A professional-grade machine can help regulate temperature and pressure evenly, further enhancing the transfer quality. By perfecting the heat transfer techniques, DTF printers can guarantee that their designs maintain their vibrant colors and intricate details over time, making them a hit with consumers. Staying informed about best practices in this area is key for anyone looking to elevate their DTF printing game.

Tips for Maximizing DTF Printing Efficiency

Efficiency in DTF printing can be significantly improved by adopting effective strategies, particularly when using the DTF Gangsheet Builder. One essential tip is to always consider the design layout carefully, ensuring that designs are grouped logically to minimize wasted space. By optimizing layouts, users can not only enhance production rates but also reduce the amount of film and adhesive used, leading to lower operational costs.

Another tip is to continuously monitor and adjust printer settings based on the specific job requirements. Staying updated with manufacturer guidelines and experimenting with various ink limits can help users achieve optimal print quality. Additionally, engaging with online communities can provide support and inspiration as others share their best practices and experiences with DTF printing. Building a network of resources is invaluable in refining techniques and staying ahead in the ever-evolving world of garment decoration.

Exploring Resources for DTF Printing Mastery

To master DTF printing and the usage of a DTF Gangsheet Builder, leveraging available resources can greatly enhance understanding. Video tutorials on platforms like YouTube offer visual step-by-step processes that clarify complex techniques. These tutorials often cover a wide range of topics, from initial design processes to the intricacies of heat transfer and adhesive application, making it easier for beginners to grasp all aspects of DTF printing.

In addition to video resources, manufacturer’s websites frequently feature comprehensive FAQs, guides, and forums where users can find solutions to common challenges. These resources are specifically tailored to the products they supply, allowing users to understand the best practices and troubleshooting tips for each printer or material. Taking advantage of these educational materials can empower DTF creators to elevate their printing skills and expand their business effectively.

Frequently Asked Questions

What is the DTF Gangsheet Builder used for in DTF printing?

The DTF Gangsheet Builder is a tool designed to optimize the Direct-to-Film (DTF) printing process by allowing multiple designs to be printed on a single sheet. This method maximizes production efficiency, minimizes material waste, and simplifies the workflow for garment decoration professionals.

How do I use the DTF Gangsheet Builder effectively?

To use the DTF Gangsheet Builder effectively, prepare your designs using graphic design software, print them onto transfer film, apply adhesive powder, and then use a heat press for transfer. Following the proper steps ensures high-quality results and efficient use of materials.

What are essential DTF printing techniques to consider when using a Gangsheet Builder?

Key DTF printing techniques include ensuring your designs are formatted correctly, selecting the right printer settings, applying adhesive powder evenly, and adjusting heat press conditions based on the fabric type. Mastering these techniques will enhance the effectiveness of the DTF Gangsheet Builder.

Can I find a gangsheet tutorial for using the DTF Builder online?

Yes, numerous resources, including YouTube tutorials and vendor websites, offer comprehensive gangsheet tutorials. These guides provide step-by-step instructions and tips for effectively using the DTF Gangsheet Builder in your printing projects.

What materials do I need for applying adhesive powder in DTF printing?

For applying adhesive powder in DTF printing, you’ll need the printed transfer film, adhesive powder specifically designed for DTF applications, and heat sources like a heat press to ensure proper adhesion. Choosing high-quality materials is crucial for achieving durable prints.

What advantages does the DTF Gangsheet method offer for garment printing?

The DTF Gangsheet method provides several advantages, including increased production efficiency, reduced waste, and the ability to print multiple designs in one go. This technique allows for flexibility in fulfilling custom orders, making it ideal for businesses in the garment printing industry.

| Step | Description |

|---|---|

| 1. Design Preparation | Prepare your designs using graphic design software, ensuring correct formatting for gangsheet layout. |

| 2. Filming and Printing | Use a DTF printer to print designs onto transfer film. Adjust printer settings for optimal quality. |

| 3. Adhesive Application | Apply adhesive powder over printed designs and melt it using heat for a strong bond. |

| 4. Heat Transfer | Position the gangsheet on fabric and use a heat press machine to transfer designs. |

| 5. Final Steps | Peel the film away to reveal the transferred vibrant designs on the garment. |

Summary

The DTF Gangsheet Builder is a powerful tool that revolutionizes the garment printing industry by enabling efficient printing techniques. This tutorial has provided a step-by-step guide to mastering the process, from design preparation to final heat transfers, ensuring that creatives can maximize their productivity and output quality. Utilizing the DTF Gangsheet Builder means you can produce eye-catching, high-quality designs with minimal waste, making it an indispensable asset for those looking to thrive in the competitive world of printing. Stay updated with emerging techniques and resources to further enhance your DTF printing skills and achieve exceptional results.